Our image film

DEPAC stands for safety: Safety in the process industry, safety in facility operation – and safety in profitability. And this for over 40 years.

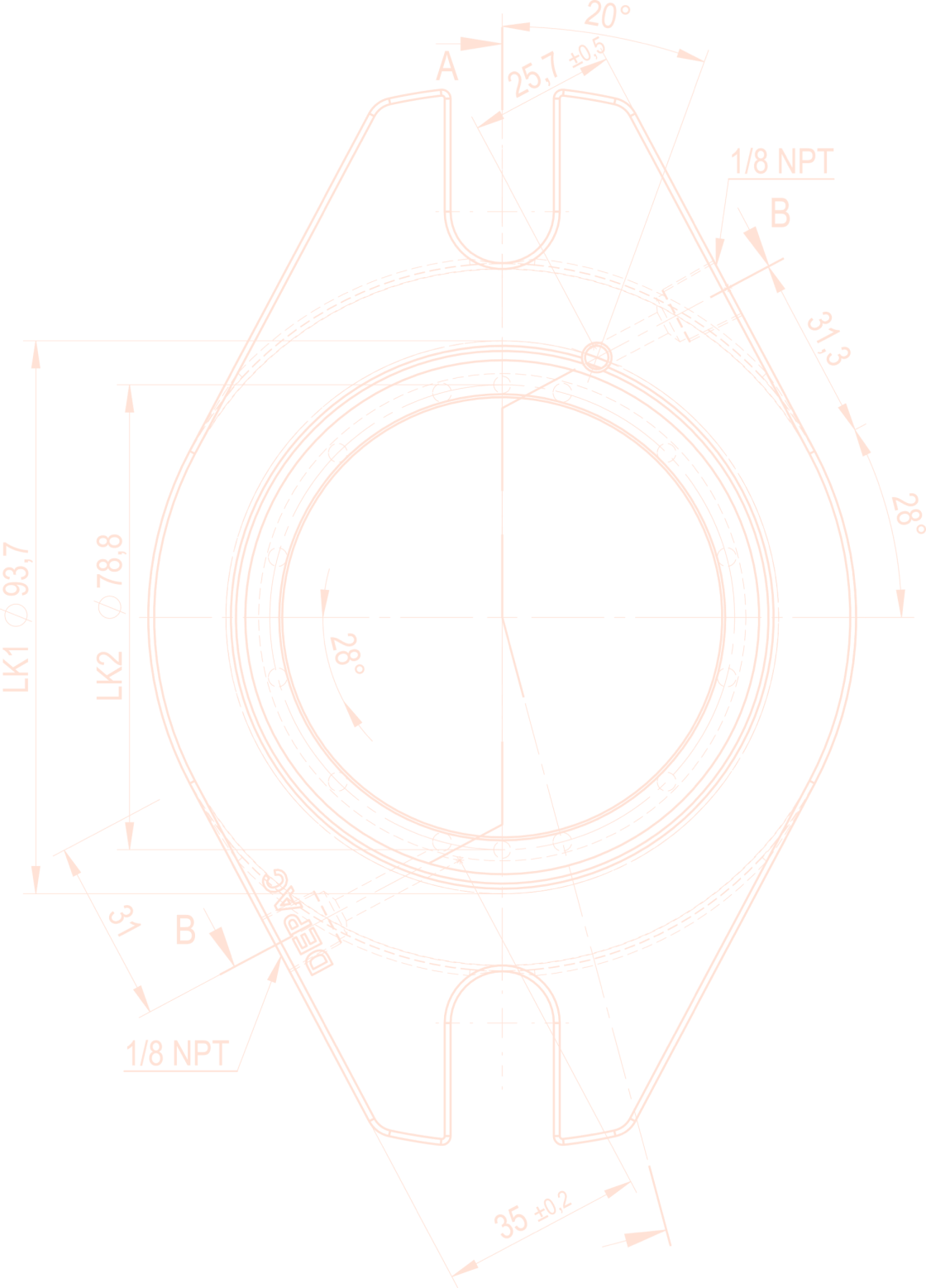

DEPAC focuses on process and operational reliability as well as market transparency. That's why DEPAC trusts in the stationary mechanical seal design, because a hydraulic, non-balanced mechanical seal transmits not only the spring pressure, but also the hydraulic pressure on the mechanical seal faces. More pressure means more friction - and consequently greater heat development. That in turn increases the wear in a mechanical seal and shortens its service life. Despite that: there are still a great many hydraulic, non-balanced mechanical seals in use in the process industry today. As an alternative, the stationary mechanical seals from DEPAC are regarded as extremely reliable and durable. Our extensive range of mechanical seals for pumps and compressors as well as for agitators, mixers, fermenters, filters and reactors can be found here. Our experts will be glad to help you find the right mechanical seal to suit your requirements.

In addition to mechanical seals, DEPAC carries a range of high-quality packings. That's because those who save on the price of packings risk expensive maintenance work, repairs and production standstills. These costs are out of all proportion to the costs of top-quality packing rings in a stuffing box. DEPAC packings are optimised for different operating conditions. Our extensive range can be found here. Our advisors will be glad to help you choose the right packing for your application!

Hydraulic seals from DEPAC are designed in accordance with the latest technical findings. The unique polymer material with homogeneous lubricant portion ensures a virtually unlimited shelf life - even when stored for lengthy periods. In addition, the positive lip form of the DEPAC hydraulic seals wipes dirt and foreign matter away. Without leakage, with little friction - and minimum wear. The range of hydraulic seals can be found here.

DEPAC has a range of high-quality maintenance aids for production plants, industrial plants and workshops. Our products are subdivided into the categories cleaning and degreasing, metal processing, lubrication and protection, maintenance and sealing, and conservation, protection, priming and maintenance. A series of so-called COMTEC products is also available to DEPAC customers. Studies have shown that 80 percent of all machine, device and unit failures in industry are attributable to the failure of faces. Our daily life is thus unimaginable without high-performance polymer composite systems. DEPAC reacted early to these challenges - and has a large number of high-quality products on offer.